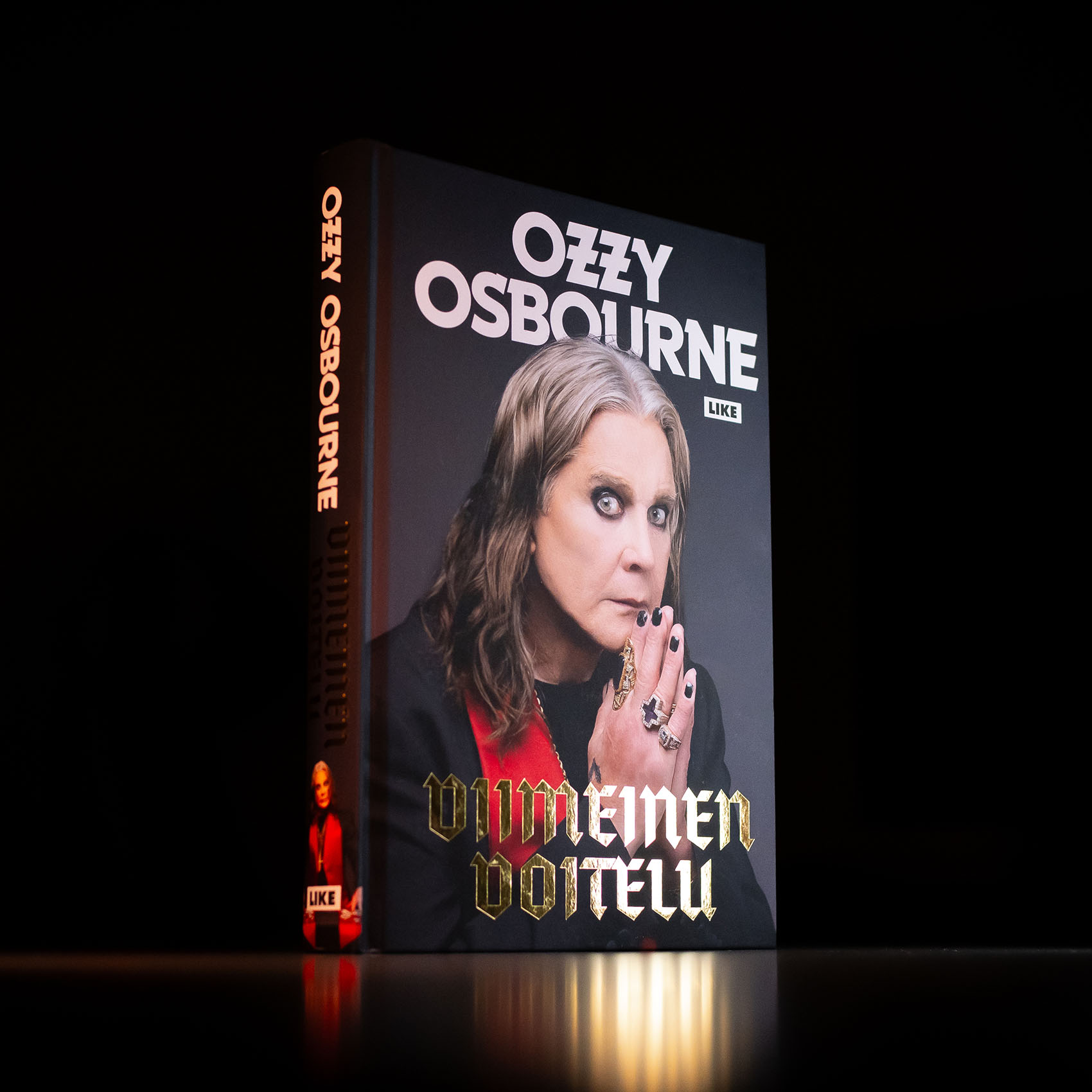

See how cold foiling is done

Watch the video to see how a book cover gets a stunning golden shine using cold foiling.

Note: The video shows a test run. The book’s production run was produced using the traditional hot foil technique.

Guidelines | Cold Foil

Sheet sizes:

minimum: 210 x 280 mm

maximum: 1040 x 730 mm

Send us the area to be hot foiled in positioned 1:1 PDF-file. Use black or other spot colour as hot foil area and white as background. The minimum distance of hot foil area from the start of the sheet is 15mm due the gripper marging.

The recommended minimum line and gap widths depend on the printed substrate, but as a general design guideline the following value should be used:

– Standard cold foil printing on coated or laminated paper and board: 300 µm

The minimum line widths for special materials, such as uncoated special paper and cardboard or embossed materials are bigger than mentioned above. We are more than happy to guide you in this matter.